General |

| Crystallization Methods |

Sitting Drop |

| Ambient temperature |

4 to 30°C |

| Computer requirement |

PC with Windows 11, 10, 8 or 7 |

Vapor Diffusion Method

|

| Volume of droplet |

0.1 + 0.1 to 8.0 + 8.0 microliters |

| Plates accommodated |

All high quality plates can be used |

| Number of wells dispensed |

1 to 96x5 |

Microtips

|

| Number of bores |

2, 3 or 4 |

| Cross-section of microtip at tip |

0.45 - 0.95 mm |

| Cross-section of each bore |

150 micron I.D. |

| Dead volume |

Zero |

| Material |

Transparent flexible water repellent fluoropolymer (FEP). Protein

channel is treated to prevent the air-bubble from breaking up. |

Liquid Handling Accuracy

The CV (coefficient of variance) has been measured using 50% PEG 4000 and 95% PEG 600 (with 5% red dye) as follows.

|

| CV for 1 µl total drop volume |

3% |

| CV for 200 nl total drop volume |

5% |

| CV for 100 nl total drop volume |

6.5% |

Universal Syringe Driver

|

| Number of discrete steps for syringe volume |

More than 22,000 |

| Displacement for each step |

3.2 microns |

| Volume dispensed per step with a 100 microlitre syringe. |

5.2 nl |

| Maximum speed |

4.0 mm/second |

Accuracy of Universal Syringe

Driver |

| R.M.S. error per step |

+/- 8% |

| Nominal maximum error per step |

16% |

| Nominal maximum cumulative error over complete linear

displacement |

2 steps |

Automatic XYZ Plate Loader

|

| Linear displacement of table: |

| travel, first horizontal axis (X) |

130 mm |

| travel, second horizontal axis (Y) |

130 mm |

| travel, first vertical axis (Z) |

48 mm |

| Nominal maximum cumulative error over complete linear

displacement |

0.1 mm |

| Length required on bench |

285 mm |

| Depth required on bench |

570 mm |

| Height in extended position |

340 mm |

| Weight |

6.5 kg |

| Time taken to dispense 96 well 1 drop experiment into e.g. SwissCI MRC 2 drop plate |

<10 min |

| Maximum speed: |

| X |

55 mm/s |

| Y |

55 mm/s |

| Z |

25 mm/s |

| The speed is software controllable and is fully

variable |

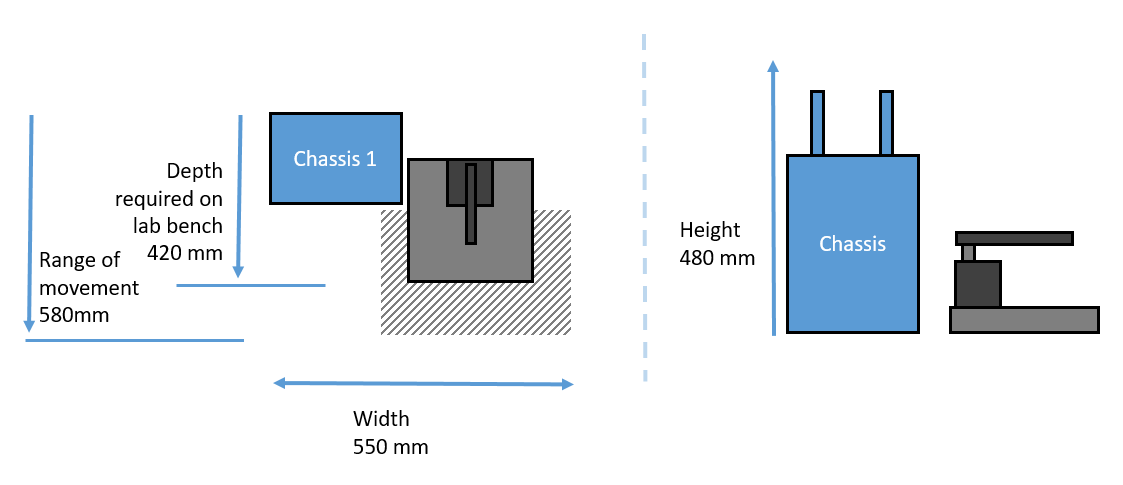

Chassis

|

| Width |

270 mm |

| Depth |

200 mm |

| Height |

450 mm |

| Weight |

8kg |

No. of Chassis Units

|

| OryxNano |

1 |

| |

OryxNano Minimum space required

|

Minimum space required for OryxNano in minimum depth configuration.

(Other configurations are possible)

|

|