|

The Douglas Vapor Batch Plate is designed for both microbatch and vapor

diffusion (sitting drop) crystallization. It has 96 wells in the center and

several reservoirs around the outside. The reservoirs can be used to

preserve microbatch crystals by preventing drying out of the wells, or they can

be used for simple vapor diffusion experiments where up to 96 wells are

equilibrated against a single precipitant (preliminary experiments suggest that

this method finds more hits in screening experiments than the conventional

method of using the same solution in the reservoir and the drop).

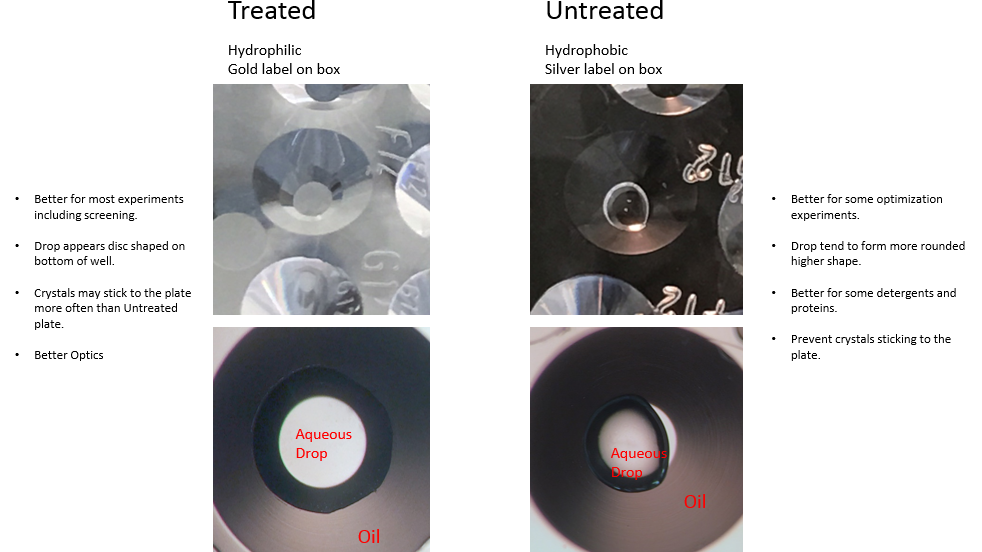

Two versions of the Vapor Batch plate are available: treated (hydrophilic) and untreated (hydrophobic). We recommend the treated hydrophilic version for most applications including screening.

The untreated hydrophobic plates are useful for some optimization experiments and for some detergents and proteins. Experiments dispensed to the treated hydrophilic plates tend form disc shaped drops whilst experiments dispensed to

the untreated hydrophobic plate tend to form rounder taller drops - Please see example drops in image below

Advantages:

Prevents leakage of oil from microbatch experiments

Wells are individually labeled

96 wells (with a 4.5 mm spacing)

Can be filled with 8-channel pipettes (transferring 6 drops at a time) by

filling odd numbered wells first, then even numbered wells

Suitable for microbatch crystallization

Suitable for vapor diffusion experiments where many drops are equilibrated

against one reservoir solution

If crystals are not obtained in vapor diffusion experiments, the concentration of the reservoir solution

can easily be increased

Because wells are smaller than Miniplates, HLA or Terazaki plates, they

are more suitable for drops below 0.5 microlitres

Available as a hydrophilic version for screening or a hydrophobic version

for optimization. (The hydrophilic version gives better liquid

handling with small volumes, while the hydrophobic version reduces crystal

nucleation and helps to prevent the crystals from sticking to the plastic)

If water or salt solution is placed in the reservoir wells of a microbatch

experiment this will prevent the wells from drying out. Microbatch

crystals will then last for up to several months.

Suitable for the transport of crystals (plates can be turned upside down

without harming the drops)

Please click here for detailed instructions for

using the Douglas Vapor Batch Plate.

Holders are available from Douglas Instruments to provide a regular Linbro

or SBS ( i.e. regular 96-well) footprint.

The Douglas Vapor Batch Plate was designed and is manufactured by Douglas Instruments.

It is available to purchase directly from Douglas Instruments.

Specification

| Material |

Medical grade polystyrene |

| Length of plate at the base |

81 mm |

| Width of the plate at the base |

55 mm |

| Height of the plate with the lid on |

20 mm |

| Number of wells |

96 |

| Shape of wells |

Truncated cone |

| Width of well at the top |

3.8 mm |

| Width of well at bottom |

1.1 mm |

| Depth of well |

1.8 mm |

| Volume of well |

9.3 microlitres |

| Typical volume of drop used in wells |

0.4 microlitres ( i.e. 0.2 + 0.2) using robot, 2 microlitres

( i.e. 1 + 1) by hand. |

| Minimum volume of drop used in wells |

No limit |

| Maximum volume of drop used in wells |

Approx. 20 microlitres. |

| Number of reservoirs |

4 reservoirs, each divided into three or four

sections. (Reservoirs are in communication with all wells.) |

| Volume of each section of reservoirs |

1 ml |

| Total volume of reservoirs |

14 ml |

Ordering information

| VB-SILVER-2/1-80

|

Untreated hydrophobic Vapor Batch plates - box of 80

plates |

| VB-GOLD-2/1-80 |

Plasma treated hydrophilic Vapor Batch plates - box of

80 plates |

| VB-SILVER-2/1-10 |

Untreated hydrophobic Vapor Batch plates - box of 10

plates |

| VB-GOLD-2/1-10 |

Plasma treated hydrophilic Vapor Batch plates- box of

10 plates |

To request a quotation please visit the Product page.

|